Glass Fused To Steel Tanks

What Exactly Are Glass-Fused-To-Steel-Tanks ?

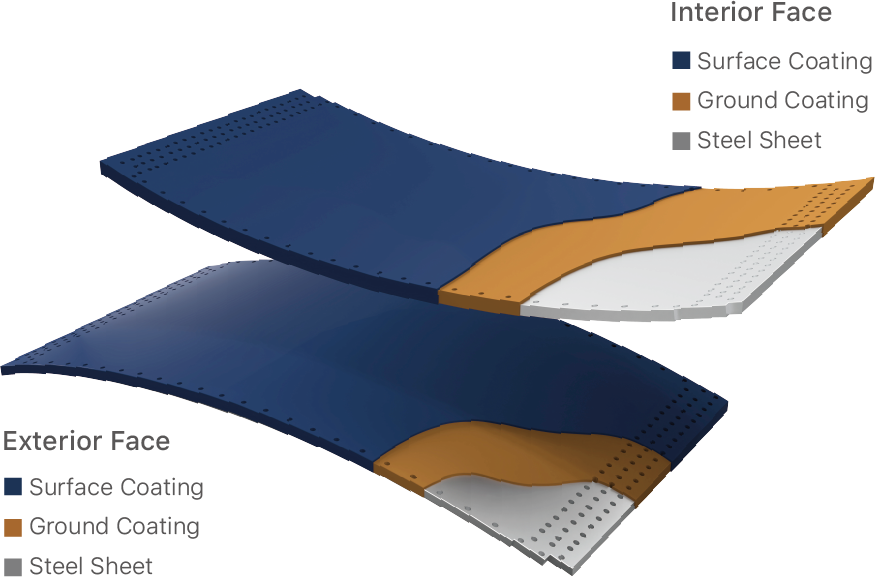

Glass fused bolted steel tanks are made through the process of firing at 820°C-930°C high temperature, the molten glass reacts with the steel plate surface to form an inert and inorganic bond, which combines the strength and flexibility of steel and outstanding corrosion resistance of glass, so Glass-Fused-to-Steel tanks can provide many advantages over standard epoxy or welded painted storage tanks. Glass-Fused-to-Steel technology is the premium coating technology in the storage tanks market, and Glass Fused to Steel tanks are widely used in drinking water, bio-energy, municipal sewage and industrial wastewater treatment etc.

Our GFS/GLS tanks are NSF61 certified for drinking water system component health effects.

Benefits And Advantages:

Tank construction that is quick and economical

Portable and can be taken apart, moved and removed.

Exquisite look & customizable tank colour

Superior corrosion resistance and service life of more than 30 years are the major highlights of glass fused bolted steel ranks